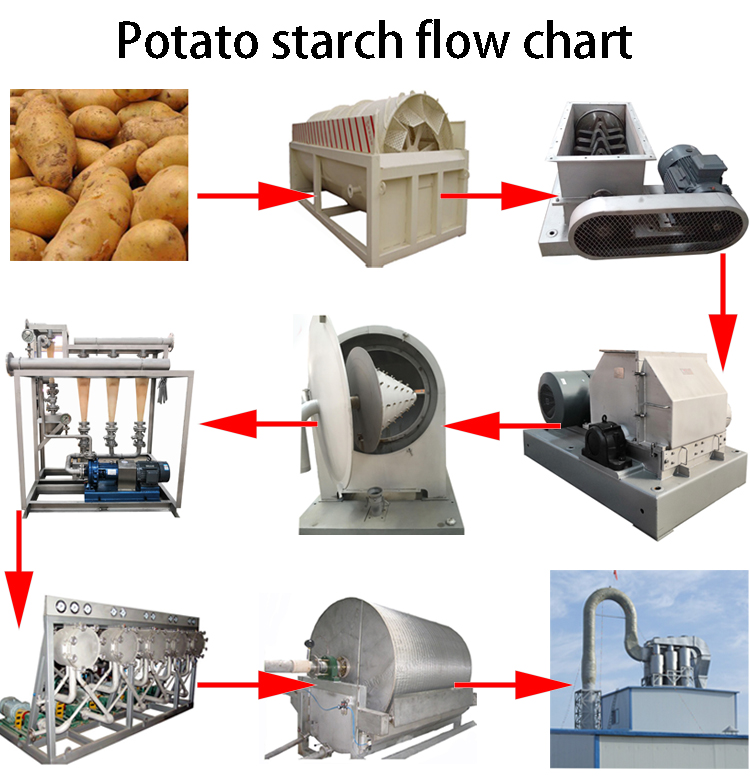

Sweet potato starch processing equipment is fully automatic sweet potato starch processing equipment, and the processing process of sweet potato starch processing equipment is:

Sweet potato → (cleaning conveyor) → cleaning (cleaning tumbler) → crushing (crusher or file mill) → separation of pulp and residue (pressure curved sieve or centrifugal sieve, pulp and residue separation garden sieve) → sand removal (sand remover) → protein fiber separation (disc separator, cyclone unit) → dehydration (centrifuge or vacuum dehydrator) → drying (low-temperature low-tower airflow starch dryer) → packaging and storage.

The selection of sweet potato starch processing equipment can choose sweet potato starch processing equipment with different configurations from the aspects of starch processing method, equipment processing capacity, equipment material, positioning of finished starch, etc., combined with its own processing needs. In the crushing section, Kaifeng Sida engineers specially designed a high-level sweet potato starch grinder, which adopts the double crushing process of “cutter + crusher + grinder”. The material grinding coefficient is high, the raw material crushing rate is as high as 95%, and the starch extraction rate high.

There is also a kind of starch that is suitable for most farmers to self-process starch. Generally, the output is not large, and the processing process is simpler. The simple production line is cleaning-crushing-filtration-sand removal-sedimentation tank-drying.

The high-yield and high-starch sweet potato has white flesh, a high percentage of large potatoes, and a starch content as high as 24%-26%. The maximum yield per plant can reach more than 50 kg. Products such as sugar, anhydrous glucose, oligosaccharides, sorbose and sweet potato alcohol have been widely used, with considerable economic benefits and promising market prospects. Mainly manifested in the following aspects:

1. Production of sweet potato purified starch

The cost advantage of my country’s sweet potato purified starch in international competition is obvious. Every year, South Korea imports sweet potato purified starch from China and the vermicelli produced with purified starch reaches more than 50,000 tons; Large, more than 1 million tons are needed every year. At present, the total amount of purified starch produced in China is less than 300,000 tons. Therefore, there is a large domestic market.

2. Production of sweet potato modified starch

Modified starch is a kind of starch that has many uses by changing its starch structure and properties through physical, chemical or enzymatic treatment. Widely used in food, paper, textile, petroleum and other industries.

3. Production of sweet potato nutrition and health starch and its products.

People’s dietary concepts have gradually shifted from food and clothing to nutrition and health care, and from a single function of food to a variety of functions. For example, adding fresh vegetable juices and fruit juices of various colors to ordinary sweet potato starch can make colorful nutritious vermicelli, colored nutritious powder skin, etc.; Health-care traditional Chinese medicines such as yam can be made into health-care powder skins with different functions.

4. Production of green packaging materials, etc.

Using sweet potato starch as the base material, it can be made into fully decomposed, non-toxic green packaging materials and agricultural films, using fully degradable starch foaming technology to produce disposable leather goods, which can be made into fertilizer or feed after recycling, and completely hydrolyzed within 60 days after being discarded . Therefore, this is a promising industry supported by environmental protection to eliminate “white pollution”.

Post time: Feb-20-2023