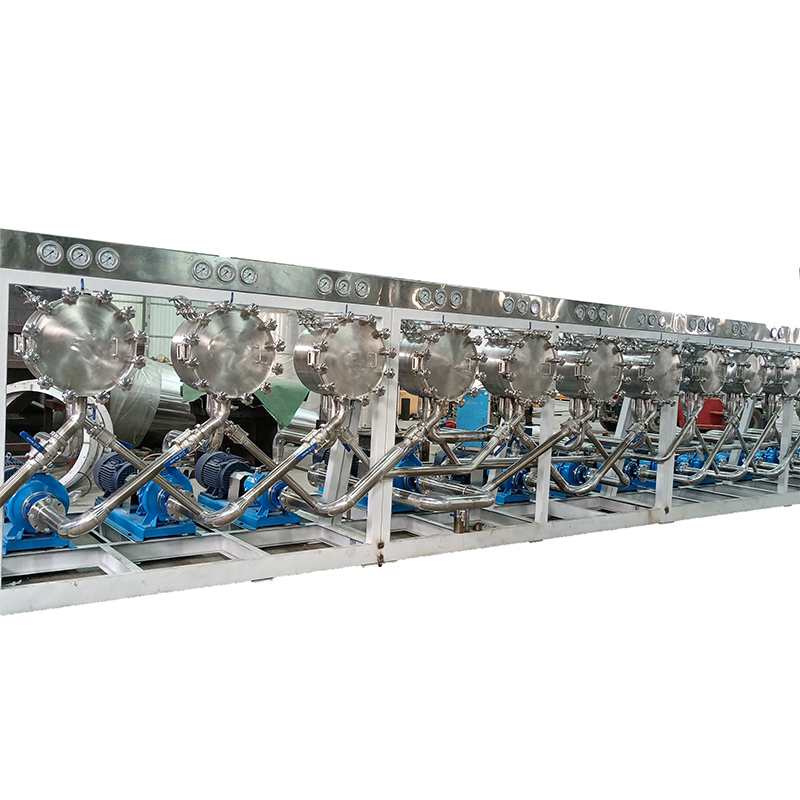

The cyclone station is composed of a cyclone assembly and a starch pump. Several stages of cyclone stations are scientifically knitted together to jointly complete refining work such as concentration, recovery and washing. Such several-stage cyclones are multi-stage cyclones. Streamer group.

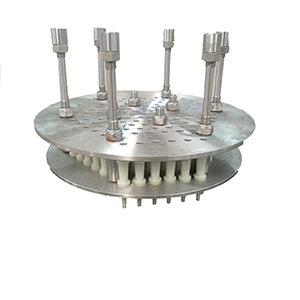

The cyclone assembly consists of a cyclone cylinder, a door cover, a sealing adjustment bolt, a large partition, a small partition, a hand wheel, a top flow port (overflow port), a feed port, a bottom flow port, and an O-shaped sealing ring. , swirl tubes (from a dozen to hundreds), etc. The cylinder is separated into three chambers: feed, overflow and underflow by partitions, and is sealed by an O-ring.

The work of the multi-stage cyclone group is mainly completed by dozens to hundreds of cyclone tubes in the cyclone assembly; the cyclones are made using the principles of fluid mechanics. When the slurry with a certain pressure enters the cyclone tube from the tangential direction of the slurry inlet, the slurry and the starch in the slurry begin to produce high-speed rotating flow along the inner wall of the cyclone tube. The movement speed of starch granules is greater than the movement speed of water and other light impurities. In the variable-diameter swirling flow, the starch particles and part of the water form an annular slurry water column, which moves in the direction of decreasing diameter against the conical inner wall. Near the central axis of the cyclone tube, a core-shaped water column that rotates in the same direction will also be generated, and its rotation speed is slightly lower than the external annular water column. Light substances in the slurry (specific gravity less than 1) will be concentrated in the center of the core-shaped water column.

Since the area of the underflow hole is small, when the circulating water column emerges from the underflow hole, the reaction force generated acts on the core-shaped water column in the middle, causing the core-shaped water column to move toward the overflow hole and flow out of the overflow hole.

Installation, use and maintenance of starch equipment cyclone group:

Install the multi-stage cyclone group at the exact location according to the process requirements. The system must be placed on a level ground. Adjust the level of the equipment in all directions by adjusting the bolts on the support feet. All input and output pipes connected according to the process flow diagram must have single supports for their external pipes. No external pressure can be applied to the pipes of the cleaning system. In the multi-stage cyclone, the starch milk is cleaned in a counter-current manner. Each cyclone in the system has feed, overflow and underflow connection ports. Each connection port must be firmly connected to ensure no dripping or leakage.

Post time: Oct-08-2023